ResurrectionFirst step was to let the

weather cooperate. It took until April before we had consistent

weather in Colorado to allow the proper curing of epoxy. Warning!,

all these shots where taked when the boat was laying on her side.

You may become disoriented.

During the winter, I had the opportunity to install a two ton hoist

in GarageMahal. This consisted of a 6X4 33 ft long 9lbs per foot

I-Beam. I also ordered a 2 ton rolling trolley and 2 ton

chain hoist. Total cost, $310. This allowed me to lift

Desperado off her trailer and set her down for some serious work.

You can see said hoist in the following picture. It also allowed

me to loan my trailer out to my neighbor who needed to pickup some long

lumber from the yard.

Tip a Canoe, and a J22!

Here she lies, with taped up for a new VC-Underwater bottom job and

the rudder hanging in the foreground for a new coat too. It is

infinitely easier to work on the bottom and keel when she lays on her

side like this. Also, the top is easier to work. Only the

inside is a bit tricky.

Here is her topside, stripped of all hardware. Waiting for her

turn at the sander.

She spent about two weeks on each side as I worked the various

exterior issues.

Before I tipped her, I finished the bulkhead

replacement. Here is the bulkhead, sans trimwork with a coat of

primer over the epoxy coating.

Remember

the separation in the sump? I ground out all the delaminated

glass, and epoxied 5 new layers of glass. She seems to hold after

I layed her down on the side. There's a coat of primer on the fix,

waiting for the final finish coat.

Here's

a shot of the aft bulk head I replaced. Note the primer on the new

epoxy tape. I wanted both bulkheads painted before I installed the

benches and trim.

Here's

a shot of the cockpit being prepped for the new look. I filled the

stock non-skid with epoxy fairing compound and sanded it flush.

Not as much work as I had anticipated.

Tapping

off the non-skid allowed me to get sloppy with the application of the

new top. A combination of Interlux Non-Skid additive to West

Marine Single part poly primer. Use 3M Blue tape. It costs

three times the price of brown tape but you will feel like a million

bucks using it.

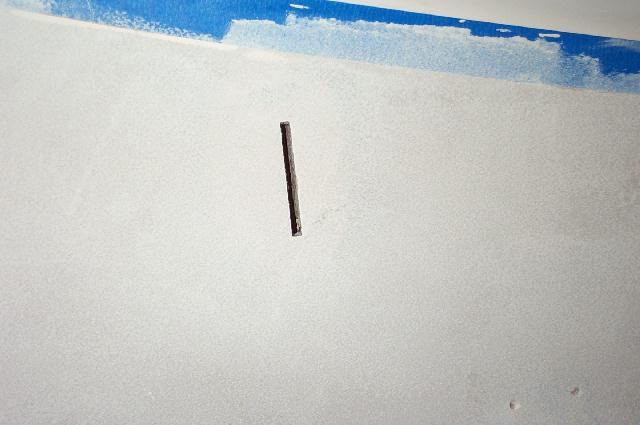

I

only rolled non-skid where the original was. Here is a shot of the

fixed chain plates. I ground out the top, dug out the rotted

balsa, and layed in thickened epoxy. I finished with epoxy with

fairing compound mixed in and pounded out the chain plates. Sanded

flush and painted with non-skid. Hopefully the plates will slide

back in!

Here's

a shot of the bow during the non-skid application. I tapped off

the stock-non-skid and applied. I will remove the tape, and spray

a nice gray single polyurethane top coat over both the non-skid and

deck, including the cabin top.

I

pulled all the tape off the hull to reveal a beautiful, epoxy bottom on

the boat. A little wet sanding and she'll be sweet!

Now to let the bottom cure enough to set her back on her trailer for the

final topside painting and refitting of the hardware. Stay Tuned!

Back on the trailer and out of the GarageMahal for some fresh air, I

prepped the sides for painting.

I

decided to do three colors on the hull. This required two stages

of painting. The center stripe first (gray) and let cure for two

days. Then taped it over to apply three coats of red on the stern

and white on the bow.

Another

shot of the hull painting. Its best to move all the cars out the

garage before spraying!

The

final product!

Maiden

Voyage, Wednesday May 30th, Chatfield Resvr, CO. With Team

Desperado. She was the talk of the club.

|